What is a CMMS Software?

A CMMS Software, or computerized maintenance management system, is a tool designed to help you handle maintenance tasks more efficiently. It lets you plan, track, and manage activities like creating work orders, scheduling maintenance, and keeping tabs on equipment or assets. Essentially, it keeps all your maintenance information in one place, making it easier to stay organized.

According to the 2024 State of Maintenance Report by Upkeep, around 72% of companies, mostly small to mid-sized ones, rely on a CMMS to streamline their maintenance operations.

With CMMS software, everything you need for maintenance is stored in one centralized system that updates in real-time. This means your team has access to accurate, up-to-date information whenever they need it, helping to keep things running smoothly.

What are the Main Functions of a CMMS?

A Computerized Maintenance Management System (CMMS) helps organizations streamline their maintenance activities. Here’s a closer look at what does a CMMS do?

- Tracking and Managing Assets

- Keeping Tabs on Inventory and Supplies

- Handling Work Orders

- Planning and Monitoring Maintenance

- Staying Ahead with Preventive Maintenance

- Analyzing Performance and Generating Reports

Types of CMMS

-

On-Premise CMMS

On-premise CMMS software is installed directly on a company's computers and servers, which means it requires your hardware and IT setup to get started. Unlike cloud-based solutions, this type of software usually involves a one-time licensing fee upfront. Once purchased, the software is fully yours to manage, giving you more control over how it works and how your data is handled.

Here’s what on-premise CMMS brings to the table:

- Total Control: Your business has full authority over the software and its data, meaning you can manage it however you see fit.

- Customizable: On-premise software offers flexibility, allowing you to make adjustments based on your specific business needs.

- Enhanced Security: Since all the data is stored in-house, you have more control over security, which could offer better protection for sensitive information.

This setup is great for businesses that prefer hands-on management and are looking for a solution they can tailor to their specific operations. While it may require more effort and resources upfront, the ability to fully own and control the system can be worth it for many companies.

-

Cloud Based CMMS

A Cloud-Based CMMS runs on the internet rather than needing to be installed on your servers. Since it's hosted by the vendor, it cuts down on the need for big investments in IT infrastructure and can reduce the need for an in-house IT support team. However, you'll need to have internet access to use it, and there will be ongoing subscription fees to keep the system running, so it’s something to factor into your budget.

Some benefits of cloud-based software include:

- Access Anytime, Anywhere: As long as you have an internet connection, you can access your system from almost anywhere.

- Flexible Growth: It’s easy to adjust as your business grows, so you don’t have to worry about outgrowing the system.

- Affordable Start-Up: With a subscription model, you won’t have to pay a huge upfront cost like traditional software, making it more budget-friendly in the beginning.

This setup makes managing your maintenance system a lot simpler and cost-effective, especially as your needs change over time.

-

Web Based CMMS

A web-based CMMS is similar to cloud-based systems, but with a few differences. While all cloud-based CMMS are web-based, not all web-based CMMS are cloud-based. Some web-based CMMS can even be hosted on-site, giving you more flexibility in how you choose to set it up.

Web-based CMMS software offers a few benefits:

- Easy Access: Since it’s web-based, you don’t need to install anything on your computer. You can simply access it through a browser from anywhere.

- Hassle-Free Updates: The software vendor takes care of updates, so you don’t have to worry about keeping it up to date—your system stays current automatically.

- Flexibility: It works across different devices, whether you’re using a desktop, tablet, or smartphone, making it easy to keep track of maintenance tasks on the go.

This kind of system makes it easier to stay on top of your maintenance needs without the technical headaches of local installations and manual updates.

-

Mobile CMMS

A mobile CMMS allows maintenance teams to access and manage their tasks right from their mobile devices. This means they can stay on top of things no matter where they are, which can be super helpful for teams that are constantly on the move. However, the overall experience and features of a mobile CMMS can depend on the device you're using and the quality of the internet connection. Most mobile CMMS software is designed to work with common smartphones and tablets, making it easy for workers to stay connected.

Some features that come with mobile CMMS include:

- On-the-Go Access: Technicians can check and update maintenance details from the field in real-time, so they don’t have to wait until they’re back in the office to report or make changes.

- Instant Communication: With real-time updates and notifications, everyone on the team stays in the loop, which helps avoid delays and confusion.

- Offline Access: In areas where the internet signal might be weak, some mobile CMMS apps offer offline features. This way, maintenance workers can still do their work and sync up with the system once they’re back online.

This kind of flexibility can streamline maintenance tasks and help keep everything running smoothly, even when the team isn’t in one central location.

How Does a CMMS Work?

CMMS (Computerized Maintenance Management System) software is designed to simplify and centralize the way businesses handle maintenance tasks. It helps keep machinery, equipment, and other physical assets running smoothly by organizing everything in one place. Here’s a closer look at what CMMS can do:

-

Managing Work Orders

One of the main features of CMMS is automating work orders. It helps create, assign, and monitor maintenance tasks, making sure the right jobs are done on time. With work orders in the system, you can track who’s working on what and what needs attention.

-

Scheduling and Resource Allocation

CMMS helps you organize your team and materials. You can assign the right people to tasks and ensure the necessary tools or parts are available when needed. This saves time and makes the process smoother.

-

Asset Tracking

A CMMS system stores all information about your assets in a central database. You can easily track their condition, history, and location. This makes it easier to stay on top of maintenance schedules and prevent unexpected failures.

-

Condition Monitoring

With the help of IoT sensors, CMMS software can monitor the condition of your assets in real-time. This feature sends alerts when something’s wrong, helping you identify problems early before they turn into costly repairs or downtime.

-

Predictive Maintenance

CMMS also analyzes past performance data to predict when equipment will need maintenance. By identifying patterns, it helps you take action before a breakdown happens, reducing the risk of sudden, expensive repairs.

-

Reporting and Analytics

The software generates reports that give you clear insights into maintenance activities. These reports help you track performance, identify trends, and make informed decisions. You can also monitor important metrics like downtime, repair costs, and asset reliability.

-

Parts and Inventory Management

Keeping track of spare parts is crucial. CMMS helps you manage inventory by showing you what parts are available, where they are located, and when new stock is needed. This ensures you always have the parts you need to keep operations running smoothly.

-

Mobile Maintenance

Technicians can use mobile devices to access the system while working in the field. They can update job statuses, report issues, and access asset details from anywhere. This makes it easier for teams to stay connected and complete tasks on time, even when they’re on the go.

-

Compliance and Auditing

CMMS software helps you maintain proper documentation for all maintenance activities. It ensures that you meet industry standards and regulations by keeping a detailed record of each job, which can be useful for audits and compliance checks.

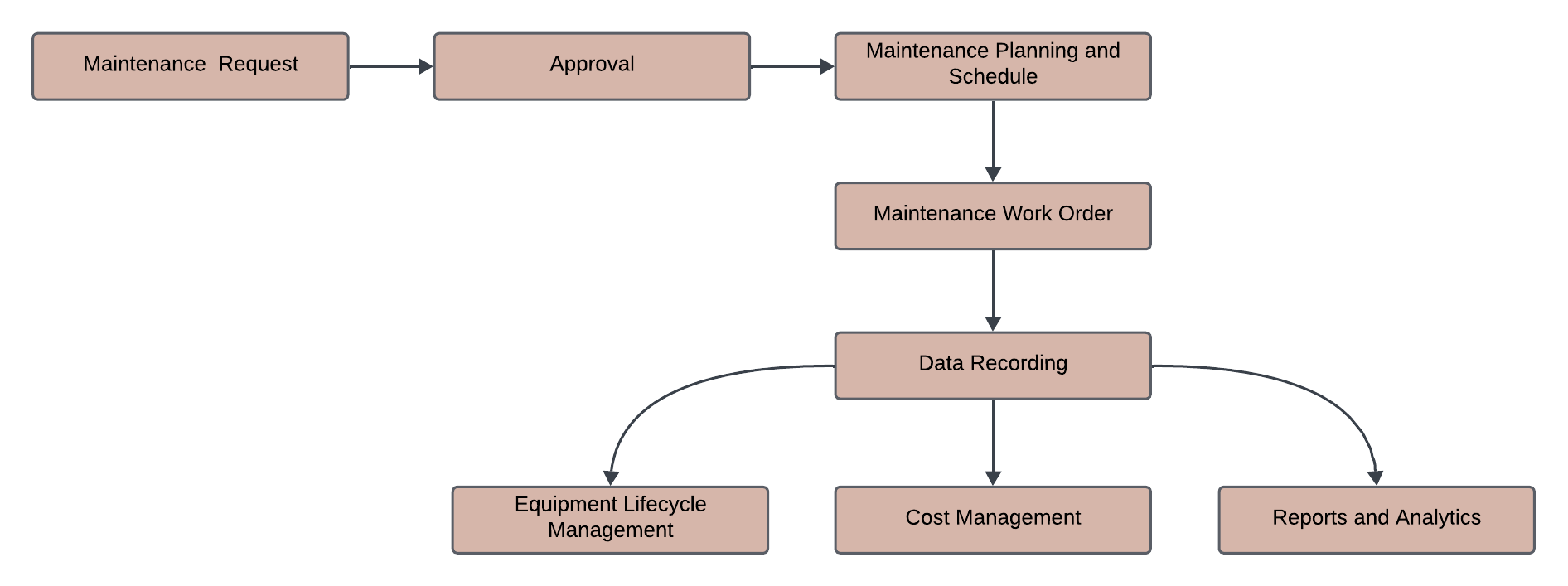

Diagram of a CMMS Workflow

Does Your Business Need a CMMS?

Before we dive into all the great benefits of a CMMS (Computerized Maintenance Management System) and how it can work for you, let’s first figure out if it’s something your company truly needs. Every business is different, but you might want to consider a CMMS if you can relate to any of the following:

- Do you work with a range of industrial equipment that needs regular maintenance?

- Are costly breakdowns of your equipment happening more often than you’d like?

- Do you manage large facilities or infrastructures like water treatment plants, hotels, shopping centers, or sports arenas?

- Are you required to meet strict hygiene, safety, or quality standards, including things like HACCP and ISO?

- Are you a service provider juggling multiple assets and clients?

- Are you still using manual methods (like paper checklists or Excel) to track maintenance tasks?

- Do you often find yourself making decisions based on guesswork instead of solid data?

- Is your maintenance team disorganized and struggling to stay on top of tasks?

- Do you have trouble coordinating and communicating with your maintenance crew?

Ready to See How NEXGEN Works?

If you nodded yes to any of these, a CMMS could be a game-changer for your business. Let's talk!

Features & Benefits of Using CMMS

A CMMS can make a big difference in how you manage maintenance tasks. Here’s a look at some of the main benefits it offers:

-

Centralized Information

If finding details about the last repair on your air conditioner feels like a hassle, a CMMS can help. It keeps all your information in one place, so you don’t have to dig through lost papers or messy spreadsheets. Once set up, it's easy to find things like work plans, maintenance logs, and instruction manuals.

-

More Productivity

A study from July 2019 found that 86.7% of companies using a CMMS saw a rise in employee productivity. Maintenance managers save time assigning tasks, and technicians can quickly find all the info they need, making their jobs smoother.

-

Less Downtime

When tasks pile up and maintenance gets delayed, equipment breakdowns are more likely. CMMS helps prevent this by making it easier to schedule, track, and review all your preventive maintenance tasks. According to the same study, 82.8% of companies saw less downtime thanks to the software. More preventive maintenance means fewer breakdowns, which helps save on costs.

-

Cost Control

Remember when we asked if you make decisions based on intuition? With the data collected by a CMMS (Computerized Maintenance Management System) and the automated reports it generates, you'll start making more informed decisions and accurately predict maintenance expenses. Because of this, about 89% of companies report improved cost control when using a CMMS.

Additionally, among the 64 companies in the study that cited a "lack of information in decision-making," only 5 continued to have this issue.

-

Increased Asset Lifetime

Approximately 88.2% of companies report that they can extend the lifespan of their assets with a CMMS. Several factors contribute to this: increased productivity (which allows for more rigorous adherence to preventive maintenance plans), fewer breakdowns, and early detection of problems thanks to quick failure reporting features.

By leveraging the capabilities of a CMMS, companies can maintain better control over costs and enhance the longevity of their equipment, ultimately leading to more efficient and reliable operations.

These are just a few of the benefits, but if you want to dive deeper, we've written a full article on the topic. Check it out here.

A Closer Look at the Industries Using CMMS

CMMS is used across various industries to help manage maintenance tasks, keep equipment running smoothly, and reduce downtime. Here’s how different sectors benefit from using CMMS:

-

Manufacturing

In manufacturing, CMMS helps manage the maintenance of machines and equipment. It tracks when maintenance is needed, so machines are serviced regularly and repairs are done before they break down. This helps keep production going without unexpected stops. The system also tracks parts inventory, so businesses don’t run out of the parts they need.

-

Construction

For construction companies, CMMS is used to keep track of the maintenance for tools and heavy equipment. It helps schedule repairs and inspections, which reduces delays on projects. By staying on top of maintenance, construction businesses can keep their expensive machinery in good shape and avoid breakdowns that could slow down their work.

-

Oil and Gas

In the oil and gas industry, CMMS helps manage the maintenance of equipment like pumps, pipelines, and drilling machines. It makes sure that regular maintenance is done to avoid breakdowns and safety issues. The system also helps businesses follow safety rules and environmental guidelines, which reduces the chance of accidents or expensive repairs.

-

Healthcare

Hospitals and healthcare facilities use CMMS to maintain medical equipment and buildings. It helps ensure that medical devices are working properly, which is important for patient safety. The system also keeps track of building maintenance, like checking HVAC systems and elevators, to make sure the facility stays in good condition.

-

Telecom and Utilities

Telecom and utility companies use CMMS to manage maintenance for equipment like cell towers, power lines, and communication systems. It helps track when maintenance is due, so repairs are done before equipment fails. The system also helps manage parts and supplies, reducing the chance of service interruptions.

-

Fleet Management

CMMS is important for fleet management, helping track the maintenance of vehicles and equipment like trucks. The system tracks repairs, fuel usage, and regular maintenance like tire rotations. This helps keep the fleet running smoothly and reduces the risk of breakdowns or delays.

-

Public Works

For public works, CMMS helps manage the maintenance of roads, bridges, and public buildings. It keeps track of repairs and preventive maintenance schedules, ensuring that everything is in good condition. The system also helps manage equipment and materials, making maintenance tasks more organized and efficient.

Supporting meteoric growth with scalable software solutions META (Formerly Facebook)

Meta (formerly Facebook) is experiencing unparalleled success while meeting the inherent challenges that come with rapid, large-scale growth over the last 12 years. A scalable, future-forward asset management system is an integral ingredient in their formula for success. With industry-leading asset management software solutions firmly in place, Meta is enjoying next-level asset performance and reduced operational downtime and costs in its facilities.

Choosing the Right CMMS

When it comes to picking the right CMMS, it’s all about finding the software that fits your team’s specific needs. You’ll want something easy to use and understand, integrates smoothly with the systems you already have, and offers fast, reliable customer support. It’s also important to take the time to research different software options, compare prices, and think about whether a cloud-based or on-premise CMMS works better for your situation.

If you’re looking for a CMMS that covers all these points, we recommend NEXGEN CMMS. Here’s why it stands out:

- Improved Productivity: Maintenance teams often see a significant boost in efficiency, with many reporting a significant improvement.

- Reduced Costs: On average, teams using NEXGEN CMMS cut production-related expenses and overall operating costs.

- Faster Repairs: With the help of NEXGEN, teams can reduce the time it takes to fix issues.

- Better Inspections: The software has made equipment inspections more efficient, with many users noting an improvement.

- Less Downtime: NEXGEN users often experience a drop in unexpected downtime related to equipment failures.

Beyond these benefits, here’s what else customers love about NEXGEN CMMS:

- It provides clearer insights into your entire operation, making it easier to keep track of everything.

- The software is simple to learn and use, so your team can get started quickly.

- It grows with your business, adapting as your needs change.

- It helps standardize maintenance practices, creating a more organized workflow.

- NEXGEN CMMS helps streamline processes, making maintenance tasks more efficient.

- You’ll have easier access to real-time data and reports, so you can make smarter decisions.

- Audits and inspections are simpler and more thorough.

- The software promotes better teamwork, with visibility that improves accountability.

- It also helps improve energy management across your business.

Customers Love Our CMMS Maintenance Software

Verified review

"It helps us with our customer and service requests, preventive maintenance, asset planning, and work order management. We advise that all of our clients use NEXGEN based on our surveys and corporate use. It is very easy to use and everyone knows about it. It integrates quite easily with most everything. Our clients have not complained about it and seems to be well suited to the manufacturing sector where we work."

Trustpilot reviewVerified review

We now have a complete and flexible product that provides us all the information that we need. Getting reports and details for our auditors is a breeze. We like that it is embedded in NetSuite and all backup is available instantly. The reporting is fantastic.

Capterra reviewVerified review

“NEXGEN Asset Management shows all maintenance completed including sewer line inspections and cleaning. This program helps us keep track of all my jobs.”

TrustpilotVerified review

"NEXGEN is a solid CMMS. Prompt customer service. Nexgen is always available for support and willing to creatively solve problems to make the software work for the customer."

G2 reviewVerified review

"We primarily use NEXGEN as a work order management system and to track timekeeping. We are using the NEXGEN 311 portal to request service internally between departments. NEXGEN allows us to keep the history of an asset through preventive and corrective work orders Reporting on this history helps us to make decisions on the life of that asset and the labor involved with its upkeep."

Trustpilot reviewVerified review

"NEXGEN is used to track our assets and their associated details, enter work orders for tracking stage and status of the work order, create preventive maintenance requests at scheduled times, compile historical data of assets, and begin to use for reliability tracking of assets. The main issue we currently struggle with is the base program does not have a great way of tracking data for cause and failure analysis, which has required us to utilize "user-defined fields" to enter and track the data. To the credit of NEXGEN, user-defined fields and customization are allowed to assist customers who are using NEXGEN beyond its actual design, which hopefully cause and failure analysis will be a near-future consideration for them."

Trustpilot reviewVerified review

“We use NEXGEN Asset Management daily to solve our work order and asset management challenges. NEXGEN Asset Management manages both horizontal and vertical assets throughout our enterprise. Our staff is in contact with up to 200 assets per day and NEXGEN Asset Management allows us to track costs, maintenance tasks, and history both in the field and the office.”

Trustpilot reviewHow to Make the Transition to a CMMS

Making the switch to a CMMS (Computerized Maintenance Management System) can really boost the way your maintenance team works. Getting the right CMMS and properly setting it up is important for the success of both your team and the organization. By following the below steps, you'll be able to choose the right CMMS software that suits your team’s needs and ensures smoother operations down the line.

- Assemble a team: Start by putting together a group of people who will help with the selection process. This team will be in charge of evaluating your options.

- Assess your needs: Take some time to figure out what your maintenance team needs. This will help you narrow down the choices that will work for you.

- Explore your options: Look into the different CMMS options available that match what you need. Don’t rush—research the ones that seem like the best fit.

- Test the top choices: Once you have a few favorites, test them out. This will help you make a final decision on the right one for your team.

Ready to Switch to NEXGEN CMMS?

Get the right CMMS and properly set it up for the success of both your team and the organization.

EAM vs CMMS

| Feature | EAM (Enterprise Asset Management) | CMMS (Computerized Maintenance Management System) |

|---|---|---|

| Scope | EAM manages all types of assets within an organization, covering everything from maintenance to asset life cycle. | CMMS mainly handles maintenance tasks, focusing on keeping equipment working well. |

| Asset Life Cycle | Looks at the entire life of an asset, from purchase to disposal. | Focuses mainly on maintenance, without covering the full life cycle. |

| Data and Reporting | Provides detailed reports and analysis, looking at various parts of the business. | Offers reports mostly related to maintenance, like work orders and repairs. |

| Complexity | EAM is more complex, handling a wide range of tasks and assets. | CMMS is simpler, with a focus on maintenance management. |

| Cost | EAM systems are usually pricier due to their broader features and capabilities. | CMMS tends to be more affordable because it focuses on maintenance. |

| Who Uses It | EAM is used by multiple teams, including maintenance, operations, and finance. | CMMS is mainly used by maintenance teams and technicians. |

| Focus | Covers everything related to assets—management, compliance, performance, and more. | Focuses mostly on keeping equipment running with maintenance tasks. |

| Long-term Planning | Helps with long-term decisions about assets and resource planning. | Primarily deals with immediate maintenance needs, ensuring smooth operation. |

CMMS Frequently Asked Questions

What is a CMMS (Computerized Maintenance Management System)?

How does CMMS differ from other maintenance management systems?

What are the benefits of implementing CMMS software?

How long does it take on average to implement a CMMS?

How does CMMS software work?

What industries commonly use CMMS solutions?

What are the key features of CMMS software?

How can a CMMS improve maintenance efficiency and asset reliability?

What are the challenges of implementing a CMMS solution?

How do ERPs work with CMMS?

How can I transition from a paper-based system to a CMMS?

What are the key considerations for selecting a CMMS software?

What are the cost-saving opportunities with CMMS implementation?

How does CMMS support mobile and remote maintenance operations?

What are the training and support options for CMMS users?

How does CMMS support preventive maintenance, work order management, and inventory control?

How do CMMS and ERP systems differ?

Why should an organization consider implementing a CMMS?

Is it possible to integrate a CMMS with other systems?

What types of training are available for CMMS users?

- Onboarding Sessions: Introduction to the software’s features and functionalities.

- Hands-On Workshops: Practical exercises to familiarize users with daily tasks.

- Advanced Training: In-depth sessions covering complex features and customization options.

How can a CMMS contribute to a company’s return on investment (ROI)?

What is the typical cost of CMMS software?

Can a CMMS replace other systems?

Is a CMMS necessary for small businesses?

How does a CMMS support preventive maintenance?

- Scheduling Tasks: Automatically generating work orders based on time intervals, usage, or condition monitoring.

- Tracking Compliance: Ensuring that maintenance activities are completed as scheduled, which helps in extending asset life and reducing unexpected failures.

How does a CMMS monitor asset history?

- Maintenance Activities: Logs of all maintenance tasks performed.

- Performance Data: Information on asset performance and any issues encountered.

- Cost Records: Details of expenses related to repairs and maintenance.

Do CMMS solutions offer technical support?

- Help Desks: Assistance with troubleshooting and resolving issues.

- Online Resources: Access to knowledge bases, FAQs, and user forums.

- Training Programs: Ongoing education to help users maximize the software’s capabilities.