Root Cause Analysis, or RCA, is an important business practice if you would like to get the most out of your organization’s processes. It’s a useful analysis tool for solving problems in any industry. If you would like to use RCA to evaluate and solve issues within your organization, utilizing a CMMS can help you do so.

What is Root Cause Analysis?

Root Cause Analysis, or RCA, is a proactive and data-driven way to figure out and solve issues during production. In other words, RCA is an informed method for problem-solving for those who want to identify and remedy issues they observe or encounter in their organization.

Root cause analysis works hand-in-hand with business processes in areas such as maintenance because it operates on the fact that it’s much more efficient to deal with problems at their root instead of tackling them as they occur. This way, you’re taking a proactive stance with your assets instead of letting them run to failure. For more on proactive or preventive maintenance.

Why is Root Cause Analysis Important?

The purpose of RCA is to assess the challenges that a company must face to streamline its processes and achieve its objectives. Therefore, identifying the root causes of a problem helps to develop more effective strategies to overcome it.

Conducting a root cause analysis and implementing appropriate solutions helps employers to significantly or completely avoid the repetition of the same or similar problems and incidents. In this way, employers help reduce the risk of death or injury to employees, the community, or the environment.

In addition, companies can also avoid unnecessary costs due to business disruptions, stricter regulations, audits, and emergency measures, just to name a few. It’s also worth noting that public trust can be gained if employers place more emphasis on prevention than on treating superficial symptoms. An accident-free track record can increase the likelihood of attracting and retaining high-performing employees, further promoting a culture of safety.

RCA Categories

Root cause analysis is not a one-size-fits-all approach. There are a lot of different tools, processes and techniques that are used to carry it out.

According to the National Association of State Mental Health Program Directors, most RCA principles fall into five main categories:

- Safety-based RCA: This process is used to investigate and identify the main causes of non-compliance with safety regulations, accident analysis, or other issues related to safety and health in the workplace.

- Production-based RCA: This is usually done in the area of manufacturing quality control to investigate the root causes of certain defects in the manufacturing process or the final product.

- Process-based RCA: This approach, which replaces production-based RCA, has been expanded to include business processes.

- Failure-based RCA: This is based on the concept of fault analysis, which is commonly used in engineering and maintenance.

- Systems-based RCA: This approach combines two or more RCA methods and also includes ideas from areas such as change management, risk management, and systems analysis.

When Should You Execute Root Cause Analysis?

Root cause analysis shouldn’t be executed when you’re encountering a one-off problem or minor issues that have only happened a couple of times. Since root cause analysis requires a lot of trial and error as well as a critical eye, it should only be applied when an organization is confronted with an issue that:

- is chronic or frequent.

- affects high-risk or critical assets.

- is dangerous to employees and their health.

By applying root cause analysis to issues such as these, organizations can mitigate or remediate potentially hazardous or financially detrimental situations before they occur again.

How to Perform Root Cause Analysis?

There are several ways that an organization can perform root cause analysis. These methods vary from organization to organization, so it’s important to find one that suits your business and its specific processes. A few examples you can try out are as follows:

Evaluate the Problem Using the 5 Whys Technique

Asking yourself “Why?” is a basic analysis skill, but those who actively practice root cause analysis ask themselves “Why?” not once, but five times. Developed by Sakichi Toyoda, who famously founded the automaker Toyota, the five whys technique helps you drill down to the root of a problem as well as come up with a solution. For example, take a look at this sample self-dialogue that utilizes the 5 whys root cause analysis technique:

- Issue: The water we treated was tested and found to have high levels of cadmium.

- Why? A galvanized pipe at our treatment plant was found to be corroded.

- Why? We were not aware of the condition of the pipe or the fact it needed replacement.

- Why? An inspection form was lost.

- Why? We keep our records using pen and paper, and someone lost the last inspection form.

- Why? Our records are kept in a disorganized room in the plant.

- Solution: Begin keeping maintenance records digitally using a CMMS so we can keep organized and up to date with our assets’ conditions.

As you can see, this is a relatively simple way to figure out what’s causing a problem and how to fix it. You can ask yourself “Why?” verbally or write out your thought process on paper, but in the end, this technique is all about thinking through an issue thoroughly so you can better understand it.

If you’ve already practiced the five whys technique to get to a solid solution, you can take this method a step further and ask yourself “How?” to come up with a path to action if you have a solution already planned out. The application for this technique is the same: simply ask yourself “How?” five times, beginning with the issue that you’ve identified using the five whys technique. When done properly, executing the five hows technique can help you get to a solution for your problem in the same way as the five whys method.

Chart out the possibilities with a fishbone diagram

Another way you can practice root cause analysis is by utilizing a fishbone (or Ishikawa) diagram. This is a useful way to find the root cause of a problem if you are someone who works well with visuals, or if you find yourself stuck in a mental rut.

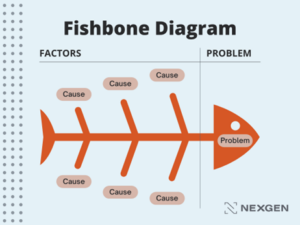

The fishbone diagram helps you identify possible causes of a problem while acting as a great foundation for brainstorming. As the name suggests, a fishbone diagram is shaped like a fish. The “spine” of the fish, denoted by a long horizontal line, represents the problem you are trying to understand. “Fishbones” branch off this line to represent six different factors of the problem. These “bones” then serve as categories for different ideas; commonly, people add more lines branching off the fishbones so they can properly visualize their ideas and how they work in tandem with the main problem and its factors. Simply put, the diagram works as a visual representation of a problem’s factors and breaks down and categorizes them.

The graphic above is just one example of a fishbone diagram. You can adjust the fishbone diagram’s categories to suit your needs; for example, in place of the “Cause” fishbones in the graphic, you can label each fishbone with categories such as these:

- Performance

- Skills

- Marketing

- Suppliers

Or if you’d prefer, you can use what is referred to as the “6Ms.” These are categories that are commonly utilized when filling out a fishbone diagram:

- Manpower

- Machinery

- Methods

- Materials

- Measurement

- Mother Nature (Environment)

Any of these categories are valid for use in a fishbone diagram. When selecting categories, we recommend coming up with a list of the top factors of the problem at hand and going from there. That way, you can make sure your fishbone diagram is uncluttered and effective.

How NEXGEN CMMS Help With Root Cause Analysis?

CMMS, or computerized maintenance management software, allows organizations to collect comprehensive records of all their assets, including basic information, historical maintenance data, and more. A more advanced CMMS and EAM solution will even give you a thorough analysis of your assets by evaluating them based on AM planning factors, thereby extending your assets’ life cycles and minimizing financial strain on your organization. Simply put, CMMS provides the foundation for root cause analysis in that it collects all your hard evidence and operational records for you. This way, you can assess problems with ease knowing that you have all the data you need readily available for viewing and interpretation.

Curious about what a CMMS can do for you? Click the button below to schedule a demo with us today.